Energy Efficiency Level History&Its Different Phases

As some energy can be lost and emerge pollution while converting it from one form to another,the goverments and bureaus are trying to regulate the min. energy convention ratio(Energy Efficiency) to reduce the pollution and protect enviroment.But the first complied regulations which include min. average convertion efficiency and maximum unload power consumption were implemented until the 21st century.

There are many countries and regions in the world, the published regulations are various from different countries and regions,to avoid any problem caused by the discrepancy,the Energy Star Bureau defined the International Energy Efficiency standard to minimize the discrepancy.The defined standard regulates the min. average efficiency and the maximum unload power consumption for external power supplies in different times along with the technical progress.

The energy efficiency level standard has gone through 6 phases and arrived the sixth phase now.Each phase level standard is represented by a Roman numeral from I in sequence,so the current phase level is Level VI.

Level I to Level V have been the past,so next we will focus on current effective Level VI standard and try to give more information on it.

To understand it well,we will give some Professional Nouns and Abbreviations explanation:

What is External Power Supply (EPS in abbreviation)?

It is a kind of power supply with designed cabinet which covert input AC voltage into lower output AC or DC current,and should be used outside of end products that is connected with wires.

Pout: Output power on power supplies nameplate.

Active Mode: The mode in which the power supply is working and its output end is connected to a load,then the output power is over zero.

No Load Mode: The mode in which the power supply is working,but the output end is not connected to anything.Or called Standby Mode.

Basic Voltage:The output voltage on the power adapter nameplate is greater than or equal to 6 volts.

Low Voltage:The output voltage on power adapters nameplate is less than 6 volt and the output current is greater than or equal to 550mA.

Level VI Requirement:

DOE Level VI efficiency standard regulates No Load power consumption cann't be greater than 0.21W for EPS ranging from 49W to 250W. It raises the mandatory average efficiency by around one percent.The regulations also expand their scope to include Low voltage EPS, Multiple Output Voltage EPS, abd output power ratings over 250 watts EPS. The effective date for the new requirements is February 10, 2016.

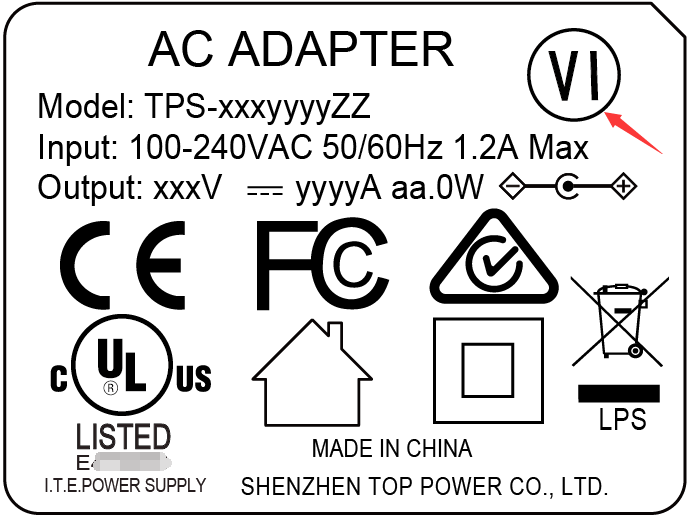

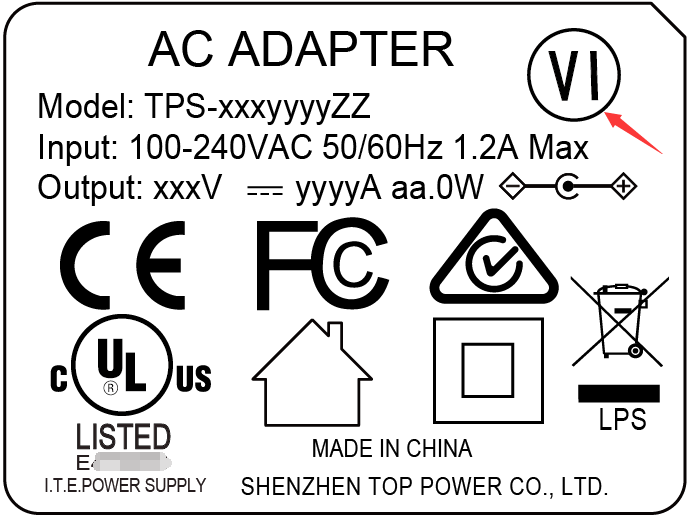

From the Roman numeral which represent the power supplies efficiency levels shown on the nameplates,it is easy to recongnize your power supplies efficiency level and select suitable power supplies for your markets.Below is an example from ShenZhen Top Power Co.,Ltd.

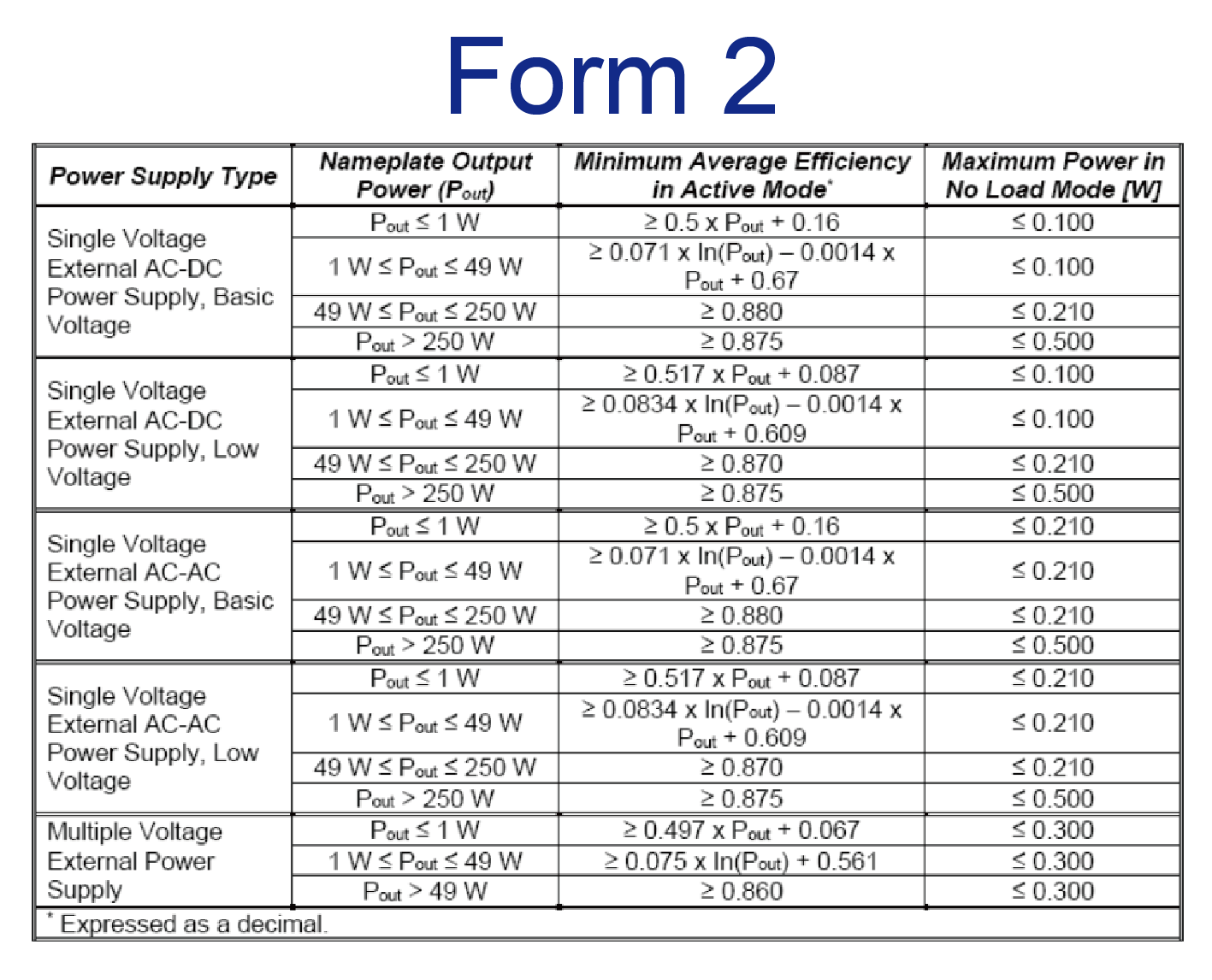

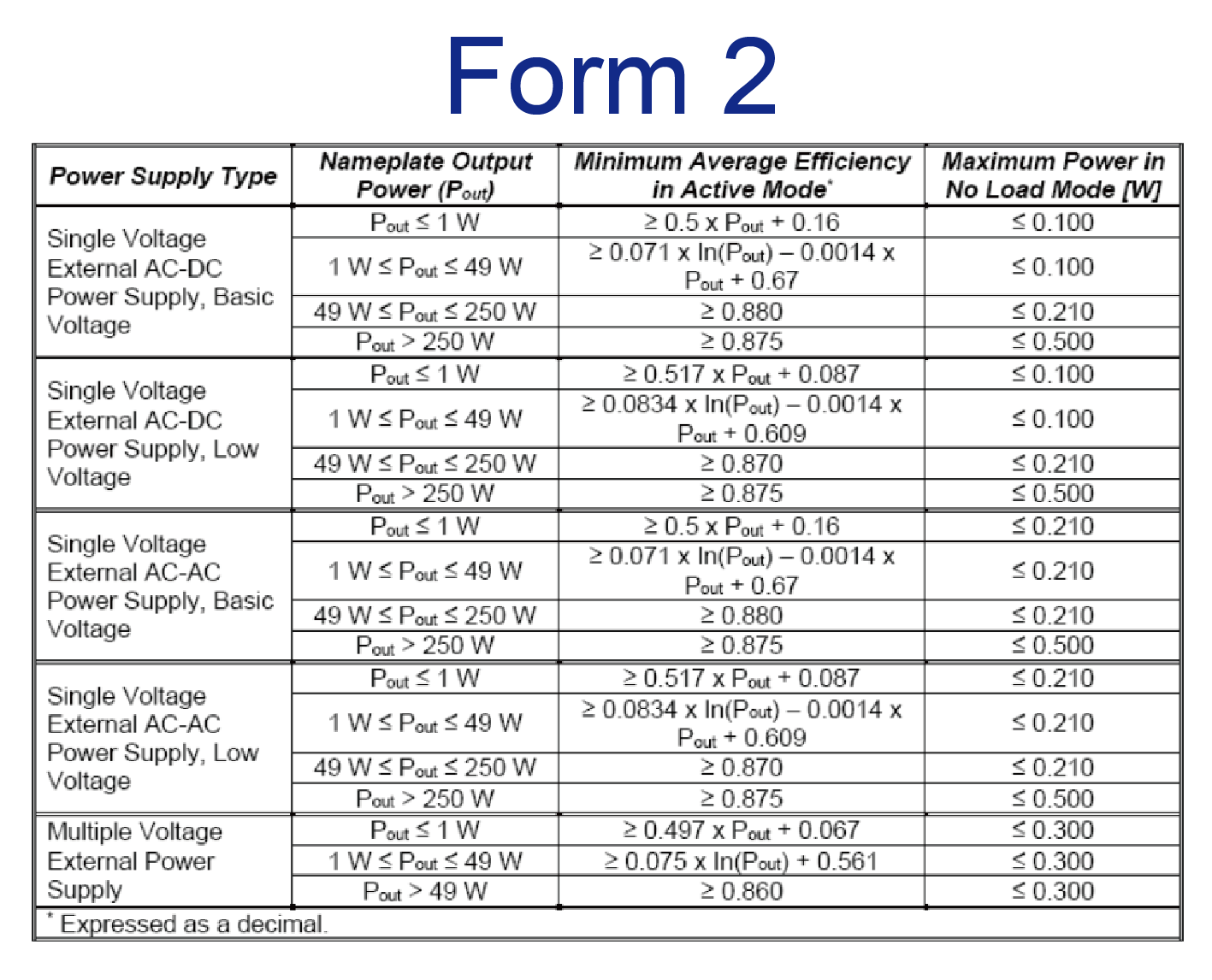

Here we only list the level VI standard of AC-DC&AC-AC single and multiple output voltage EPS,also its calculation formula in Form 2 as below:

Here we only list the level VI standard of AC-DC&AC-AC single and multiple output voltage EPS,also its calculation formula in Form 2 as below:

How to Test:

The power supplies should be tested under t115Vac 60 Hz and 230Vac 50 Hz,if its nameplate input voltage and frequency indicate that it can work safely under both conditions.The power meter shall have a resolution of 0.001W to show the No Load power consumption for all power ranges power supplies.

The power supplies shall be tested under the load conditions shown in Form 3,and output current is percentage of nameplate output current

How to Test:

The power supplies should be tested under t115Vac 60 Hz and 230Vac 50 Hz,if its nameplate input voltage and frequency indicate that it can work safely under both conditions.The power meter shall have a resolution of 0.001W to show the No Load power consumption for all power ranges power supplies.

The power supplies shall be tested under the load conditions shown in Form 3,and output current is percentage of nameplate output current

Form 3

The power supply is operated at 100% of nameplate current output for 30 minutes immediately prior to conducting efficiency measurements.

The power supply is operated at 100% of nameplate current output for 30 minutes immediately prior to conducting efficiency measurements.

After this warm-up period, the ac input power is monitored for a period of 5 minutes to assess the stability of the power supply.

The power level has not drifted by more than 5% from the maximum value observed. The power supply is considered stable and the measurements have been recorded at the end of the 5 minute period.

Measurements of power of 0.50 W or greater are made with an uncertainty of less than or equal to 2% at the 95% confidence level.

Efficiency shall be calculated by dividing the power supply’s measured output power by the actual input AC power measured at that load condition. Average efficiency shall also be calculated as the mean of the efficiency values calculated under Load Conditions 1, 2, 3, and 4.That is (Efficiency1 under load condition1+Efficiency2 under load condition2+Efficiency3 under load condition3+Efficiency4 under load condition4)/4.

It is crucial to fix a cable length before test,meantime the cable should be connected to power meter without any connectors,because there will be voltage lost on the extra cable and connectors.

Also there are special requirements of power supplies efficiency level VI in State California,it is CEC VI.

Power supplies from Shenzhen Top Power Co Ltd fully meet DOE VI and CEC VI,and can help you to sell end products in USA no limitation.If you want to get them shortly,please ask Shenzhen Top Power Co Ltd sales team for assistance.

Switching to Efficiency: The Benefits of Switch AC Adapters

Switching to Efficiency: The Benefits of Switch AC Adapters

AC Adapter Laptop Chargers: Reliable Power Sources

AC Adapter Laptop Chargers: Reliable Power Sources

Unveiling the Advantages of 60335 Power Adapters: Safety and Reliability in a Compact Design

Unveiling the Advantages of 60335 Power Adapters: Safety and Reliability in a Compact Design

How to choose a led power supply for LED lights?

How to choose a led power supply for LED lights?